According to the national “Special Action Plan for Large-Scale Construction of New Energy Storage (2025–2027)”, China’s installed capacity of new energy storage is expected to exceed 180 million kW by 2027. As of the end of June 2024, approximately 94.91 million kW has already been built, meaning that an additional 85.09 million kW will need to be added over the next two years. Among this, lithium-ion battery storage is expected to account for 80%, corresponding to 68 GW of power. With the standard “4-hour” charge–discharge design, this will result in an additional approximately 544 GWh of battery capacity.

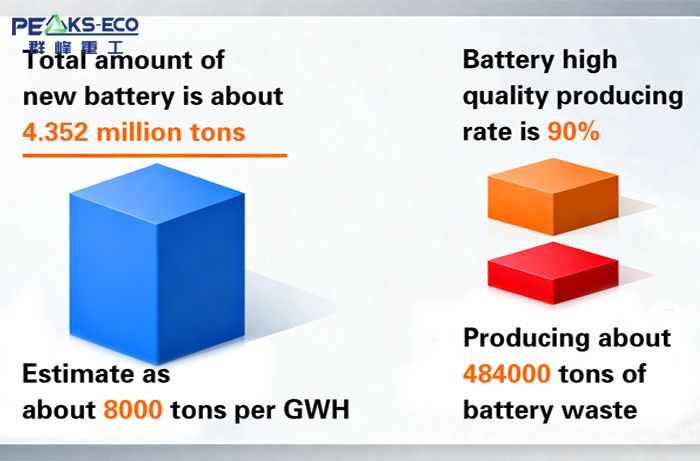

Based on an estimate of approximately 8,000 tons of lithium iron phosphate (LFP) batteries per GWh, the newly added battery capacity will total about 4.352 million tons. Assuming a 90% production yield, this will generate roughly 484,000 tons of battery waste. Among this waste, waste electrodes account for the largest share (40%, about 194,000 tons), while the remainder consists of non-electrolyte-injected batteries, defective products, and substandard items, creating significant demand for lithium battery recycling equipment and operational services.

Since 2021, China has been undertaking large-scale construction of lithium-ion energy storage facilities, with the peak of energy storage battery retirements expected to begin around 2029. At the current stage, the primary focus remains on managing battery production waste.

PEAKS-ECO, as a system solution provider in the lithium battery recycling sector, offers full-process services from waste pre-treatment to valuable metal recovery:

Electrode sheet processing: The company has independently developed systems for electrode crushing, sorting, and current collector stripping, enabling efficient recovery of anode and cathode powders while achieving clean separation of copper, aluminum, and active materials.

Defective and non-electrolyte-injected cells: PEAKS-ECO has developed intelligent crushing and fine sorting processes under an inert atmosphere, effectively mitigating safety risks and improving the recovery rate and purity of black powders.

Modular production lines: Depending on client capacity requirements, the company provides modular line design and full-line integration, covering multiple processes including discharging, disassembly, crushing, sorting, roasting, and wet recovery, helping clients achieve scalable, resource-efficient, and non-hazardous battery waste management.

In response to the upcoming peak of energy storage battery retirements, PEAKS-ECO continues to optimize flexible end-of-life battery processing technologies, offering the downstream industry safe, reliable, and cost-effective recycling equipment and operational support, and contributing to a green, circular, and sustainable energy system.

In addition, sustainable recycling processes such as the PEAKS-ECO hydrometallurgical lithium battery recycling system have been developed, using recycled liquid solvents to extract metals and return high-purity chemicals to the battery supply chain, preventing environmental pollution while saving resources.