Low-value plastics refer to plastic waste for which the cost of collection, processing, and recycling exceeds the revenue generated from selling the recycled material. Therefore, the term does not describe any specific type of plastic, but rather an economic concept— the value of a given plastic is not fixed and depends heavily on the local recycling system. In areas where recycling systems are well developed, such plastics may be considered valuable resources; but in places where processing costs are high, they are regarded as “low-value plastics.”

Typically, when we talk about low-value plastics, we are referring mainly to soft plastics and multi-layer composite plastics, which pose major challenges in current efforts to address plastic pollution.

Complex structure: Take multilayer composite plastics as an example. They are usually formed by laminating thin films made of different materials—such as plastic, aluminum foil, and paper.

This structure makes the material lightweight and effective for preservation, but it also means that recycling requires significant energy and advanced technology to separate the layers—resulting in extremely high costs.

Poor economic viability: The total cost of the recycling process often exceeds the value of the recycled material itself, leaving little market incentive.

Downcycling dominates: Many soft plastics are made from mixtures of different plastic types, which are difficult to separate precisely. They are often “downcycled” into lower-value products that are unsuitable for use as food packaging.

Due to high processing costs and complex procedures, most municipal recycling systems are unwilling or unable to accept these plastics. As a result:

In many countries, they are mostly sent to landfills or incinerated.

For example, in the UK, the recycling rate for soft plastics is only about 6%.

In areas without formal recycling systems, valuable plastics (such as rigid bottles) are often collected by informal waste pickers, while soft plastics are frequently discarded carelessly, eventually entering waterways and oceans and causing severe pollution.

Soft plastic packaging is one of the fastest-growing packaging categories, accounting for about one-quarter of consumer goods packaging. Therefore, establishing a recycling system for it is urgently needed.

The best approach depends on local conditions and infrastructure:

Recycling and circular use: In areas where conditions allow, dedicated collection systems can be established, and subsidies can be provided to offset the costs of the recycling chain. This makes collection profitable for collectors and helps prevent pollution.

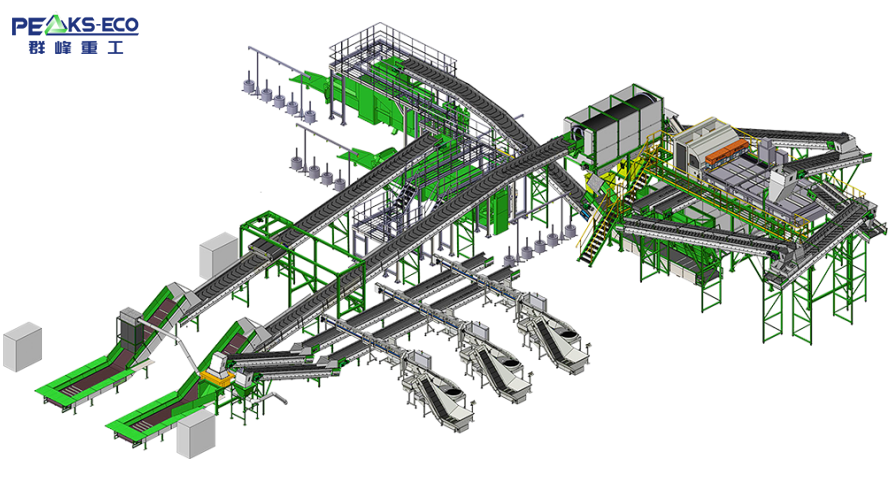

This processing line uses a continuous workflow of “feeding – screening – optical sorting – baling” to efficiently sort waste plastic bottles. Through optical sorting technology, it accurately identifies and classifies bottles made of different materials. The bottles are finally compressed and baled into high-density “bottle bricks,” facilitating storage and transportation while providing standardized raw materials for subsequent sales.

Physical transformation (upcycling): Soft plastics that have been cleaned and shredded are heated and melted to form construction materials such as “plastic-wood boards.” This method is relatively energy-efficient and gives the waste a second life.

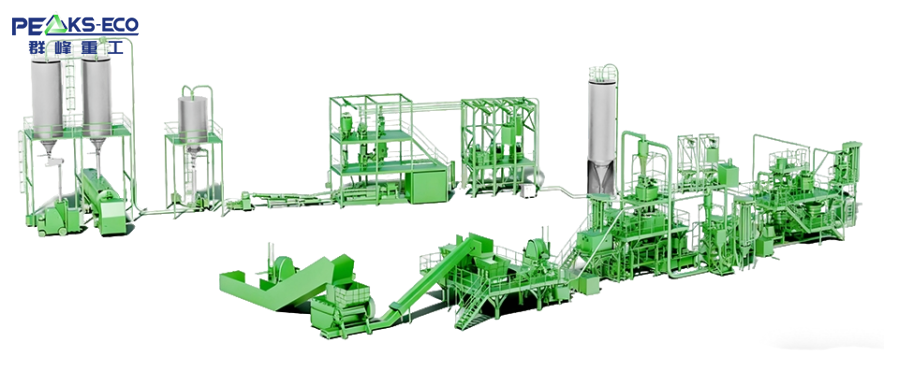

After plastics are shredded into small particles, they pass through a series of processes including reciprocating washing, hot washing, dewatering, and pelletizing. The result is clean plastic flakes or recycled plastic pellets, which can be directly used for injection molding of new products.

Co-processing: In areas lacking recycling facilities, low-value plastics can be sent to cement plants as an alternative fuel for cement production. At high temperatures, the plastics are almost completely decomposed, and the residues can be incorporated into the cement. This approach is more environmentally friendly and economical compared to landfilling or incineration.

A fundamental solution requires a multi-pronged approach:

Technological innovation: Develop packaging materials that are easier to recycle, or create more efficient and low-cost processes for recycling low-value plastics.

Source reduction: Promote reusable or refillable packaging models to reduce the use of single-use soft plastics.

Policy and responsibility: Implement regulations such as Extended Producer Responsibility (EPR), requiring manufacturers to take responsibility for the disposal of their products, thereby incentivizing the design of more environmentally friendly packaging.

Pragmatic perspective: Completely banning soft plastics is currently unrealistic due to their advantages in food preservation, lightweighting, and cost. The key is to balance their utility with environmental impact and establish a management system covering their full life cycle.

In short, the issue of low-value plastics is fundamentally an economic and systemic problem. To prevent them from polluting the environment, it is essential to combine financial investment, policy guidance, and innovative approaches to create a sustainable operational momentum across the entire collection, sorting, and processing chain.