Household refrigerators are indispensable appliances in modern homes, integrating advanced technologies from mechanical engineering, thermodynamics, and materials science. When a refrigerator reaches the end of its service life, its material lifecycle does not end. Through scientific and standardized dismantling processes, over 95% of the materials can be efficiently recycled, truly achieving a green transformation from “waste” to “renewable resources.”

Standardized dismantling of end-of-life refrigerators follows strict safety and environmental protection standards, implementing meticulous process management:

First, in the pre-treatment area, manual dismantling separates recyclable components such as plastic parts, glass, and circuit boards, while the cabinet undergoes refrigerant recovery and compressor removal. Different types of refrigerants (e.g., HC or HFC) are recovered using specialized equipment or safely vented, with the entire process strictly adhering to explosion-proof and environmental protection requirements.

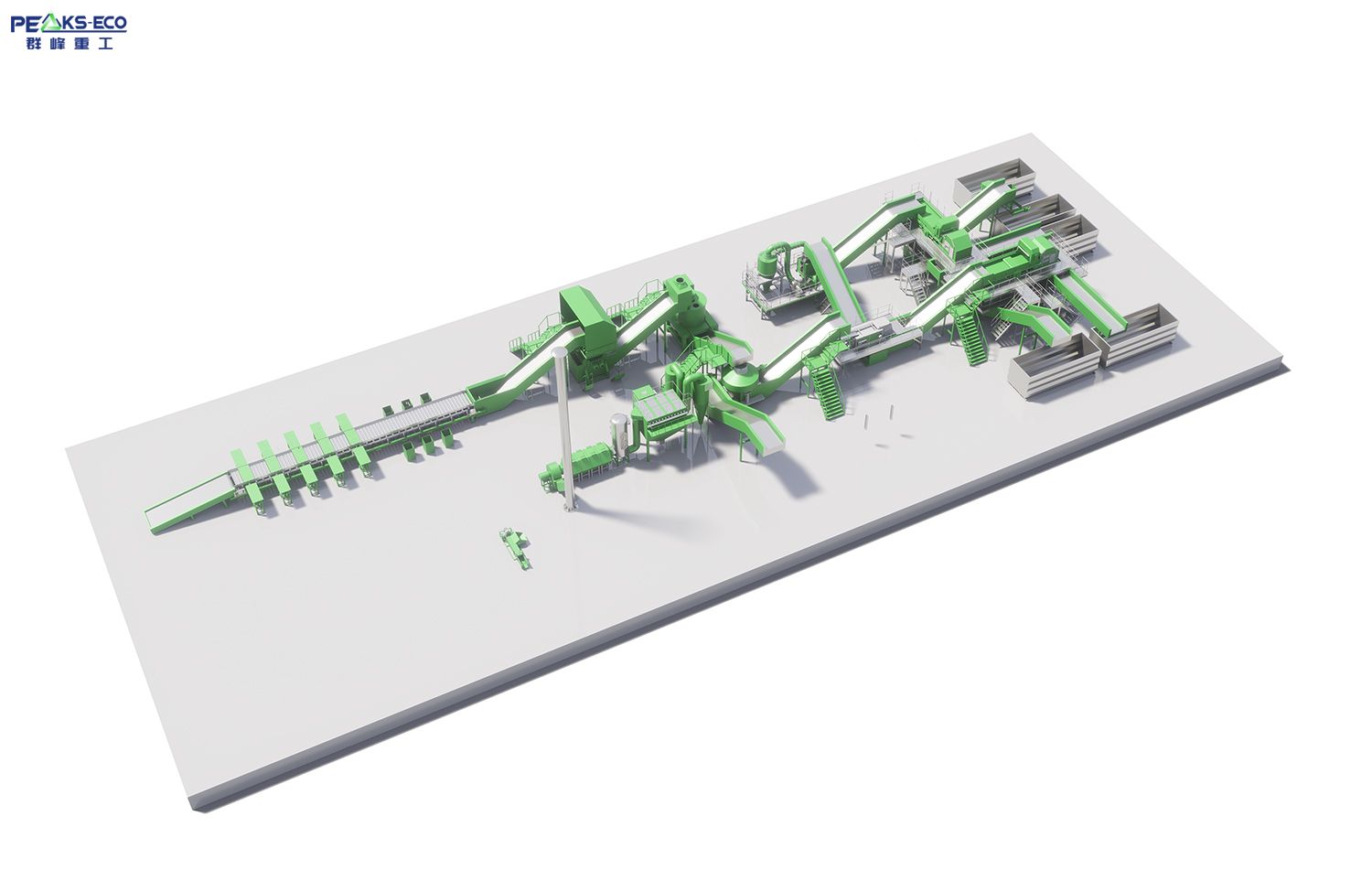

After compressor removal, it is safely processed using a dedicated oil-draining and puncturing system. The remaining cabinet is then fed through an automated conveyor system into a dual-shaft shredder and a vertical crusher for two-stage crushing, efficiently separating metals, plastics, and polyurethane foam. Advanced separation technologies such as magnetic separation, eddy current separation, color sorting, and air separation are then employed to precisely segregate iron, copper, aluminum, various plastics, and foam for recycling. The separated foam is compressed to reduce volume, and plastics are deeply purified using intelligent sorting systems.

The entire production line is equipped with intelligent environmental monitoring and safety warning systems, continuously monitoring gas concentration and temperature in key areas and issuing tiered alerts, achieving full “human-machine isolation and automated operation,” ensuring that the production process is safe, efficient, and environmentally friendly.

Systematic dismantling of refrigerators is a comprehensive engineering effort combining technology and environmental protection. It embodies the circular economy concept of “resources → products → renewable resources” and promotes standardized recycling of end-of-life home appliances. This approach not only effectively reduces environmental pollution and decreases the consumption of virgin resources but also creates significant economic and environmental benefits. We call on consumers and relevant authorities to support standardized recycling of end-of-life appliances by entrusting them to professional processing enterprises, working together to build a green, low-carbon circular economy.

PEAKS-ECO, founded in 2005, is a leading environmental solutions provider with a 30-hectare intelligent OEM/ODM manufacturing base. The company focuses on the design, construction, operation, and technological innovation of comprehensive waste treatment projects, including household appliance recycling, construction waste, kitchen waste, and industrial waste. Leveraging advanced equipment manufacturing and process technology, PEAKS-ECO provides end-to-end recycling solutions and has successfully implemented numerous large-scale waste treatment projects in China and overseas.

We call on consumers and relevant authorities to support standardized recycling of end-of-life appliances by entrusting them to professional processing enterprises like PEAKS-ECO, working together to build a green, low-carbon circular economy.