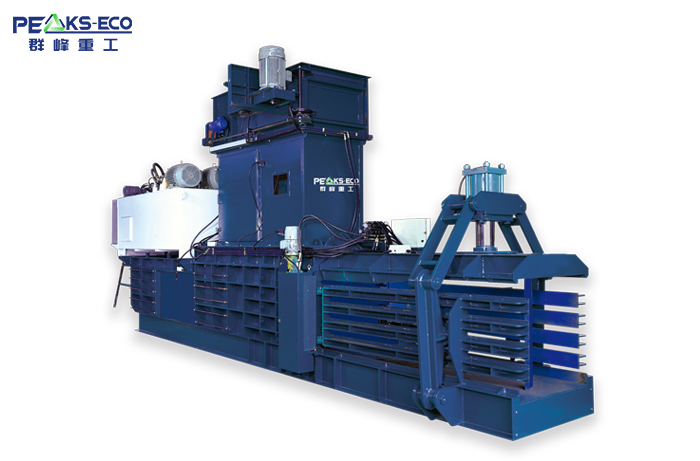

Baler is to reduce the volume of recyclable materials and produce compressed bales by using the powerful force of hydraulic cylinder. Waste Paper Baler is popularly used for continuous compression of wastes with recyclable value such as paper, cardboard and plastics; drum baler used for continuous compression of PET bottles, paper and cardboard. We also sell waste disposal balers, plastic baler machines and Agricultural produce balers.

For more than 20 years Qunfeng has been manufacturing balers and plants for all professionals operating in the paper sector: waste paper merchants and brokers, paper mills, printing plants and box plants.

The paper industry has always been a core part of our business and today our balers are the first choice of professionals operating in this sector.

Our balers can process up to more than 40 tons/hour of paper, and can be equipped with various accessories: conveyors, shredders, fluffers, dust suction systems.

As always, all our plants are customized according to specific customer requirements. But our regular baler can support FDY-850 and FDY-1250 semi-automatic baler and full automatic baler.

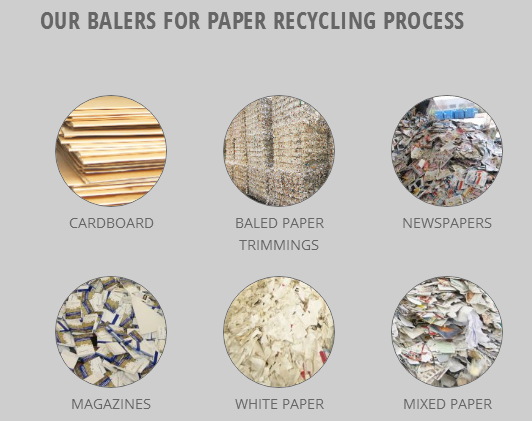

Streamline your recycling process with our paper baler and paper baler machine, designed to handle high volumes of paper efficiently. Our cardboard baler machine and industrial cardboard baler are perfect for compacting cardboard waste, making disposal and recycling easier. We also offer paper balers and waste paper baler options to suit different industry needs. With our baler machines, including the cardboard baling machine, you'll achieve space-saving efficiency. For specific needs, our make-ready waste balers provide a reliable solution. Contact us for more information.

Are you interested in purchasing one or more balers for recycling? If so, we would like to share the following tips to help you make your decision.

Consider the specific material you plan to compact, as well as your budget and available space.

Determine your needs based on factors such as facility size and usage.

Plan logistics. Will you use enclosed trailers, flatbed trailers, containers or other transportation methods?

Consider the space available in your facility and who will be operating the baler.

Paper balers or balers are part of a larger category of industrial balers. Industrial balers handle paper, cardboard, office paper and more. They also handle other materials, from aluminum to plastic packaging to automotive parts.

For any of these materials, the process is essentially the same. Apply enough pressure and you can press the bundles (bales) into a variety of sizes and shapes.

Baler is to reduce the volume of recyclable materials and produce compressed bales by using the powerful force of hydraulic cylinder. Waste Paper Baler is popularly used for continuous compression of wastes with recyclable value such as paper, cardboard and plastics; drum baler used for continuous compression of PET bottles, paper and cardboard. Automatic control by PLC and tight wire coupling can help produce tightly compressed bales and provide users with the convenient and safe operation. The compressed bales allow the users to have more storage space and transportation highly economical. Baler is typically installed on the final discharge section of MSW system.

The baler compresses and bundles the paper into large, solid bales. The baler facilitates the process of transporting paper and cardboard to a recycling facility. There, it is processed in large quantities.

Shredding is essential when preparing paper products for recycling. Once shredded (or torn), the small pieces fall through the hopper into the baler. There, it is compacted using a hydraulically driven plunger.

The coalesced material forms dense blocks. Most machines will bind the tightly compacted material together with wire or twine to keep it tightly packed until it is ready for processing.

| Model | Hydraulic system pressure | Host power | Bundle size | Bundle density | Production capacity | Features |

| FDY 850 Semi Automatic Baler Machine | 1500KN | 30KW+5.5KW+4.0KW | 1100*850*L(adjustable:1500-2000)mm | 500kg/m³ | 6-12 bales/hour | Automatic operation Space-saving vertical tying system Horizontal taping system Large hoppers and openings Variable bale lengths to meet your requirements High pressure strength produces dense bales Easy to use controls Easy to change wires |

| FDY 850 Full Automatic Baler Machine | 30KW+5.5KW+5.5KW | 7-10 bales/hour | ||||

| FDY 1250 A Semi Automatic Baler Machine | 1600KN | 37KW-4+5.5KW+4.0KW | 1100*1250*L(adjustable:1500-2000)mm | 450kg/m³ | 7-10 bales/hour | Automatic operation Horizontal tie system Oversized hopper and feed opening Variable bale length High pressure strength Easy to use touch screen controls 150 and 200 ton pressure options 10 to 25 tons per hour |

| FDY 1250 C Semi Automatic Baler Machine (Lengthen type) | 45KW+5.5KW+4.0KW | 500kg/m³ | 7-12 bales/hour | |||

| FDY 1250 D One Motor With Two Pump Waste Paper Baler Machine | 9-16 bales/hour | |||||

| FDY 1250 E Semi-Automatic With Door Baler Machine | 55KW+5.5KW+4.0KW | 5-10 bales/hour | Semi-automatic operation Manual tie down Enclosed door for enhanced compaction Large hopper and openings High-pressure strength produces dense bales Easy-to-use controls | |||

| FDY 1250 F Double Motor With Two Pump Waste Paper Baler Machine (Lengthen Type) | 37KW+5.5KW+4.0KW+45KW | 18-25 bales/hour | Automatic operation Horizontal tie system Oversized hopper and feed opening Variable bale length High pressure strength Easy to use touch screen controls 200 and 300 ton pressure options 20 to 40 tons per hour |

1. Powerful compression by hydraulic motor

2. Continuous compressing

3. Hydraulic door mode for the safety

4. Easy to maintain compression ram

5. Automatic wire connection

6. Easy operation with PLC

Most balers can easily make paper and cardboard balers. However, baling paper does not have to be the only product of these machines. Some also handle other materials commonly used in commerce and industry.

Mini balers: Capable of producing bales up to 4.6 cubic meters and approximately 79.3 kg, these balers are ideal for small businesses.

Vertical balers: Ranging in size from approximately 0.75 meters to 2 meters, these machines can meet the recycling needs of entities ranging from private residences to large manufacturing operations.

Horizontal balers: These giant machines serve entire cities, shopping centers, transfer stations and more.

Open balers: Use these efficient balers to create subsequent bales by pushing the material onto the back of the previous bale after one is made.

Full pop-up balers: Although more time consuming and labor intensive than other balers, these machines are compact and versatile (handling a wide range of materials).

Multifunctional balers: These multifunctional balers offer convenience. Plus, they can bale everything from cardboard bales to flattened and bound aluminum cans.

If you want to recycle baled materials, be sure to avoid mixing different materials when loading the machine.

Balers are often used in conjunction with other machinery such as cardboard compactors, shredders, grinders, conveyors and other equipment to make the process more efficient.

Cardboard Balers, also known as cardboard compactors or cardboard crushers, are a popular machine in industries that require efficient waste management. Since there are quite a variety of different types, ranging from smaller compact balers to large industrial balers, cardboard waste has become much more manageable than in days past.

Waste paper baler plays a very important role in paper recycling. Let us deliver the waste paper as much as possible for recycling. It greatly improves the efficiency of recycle process. On the other hand, it also helps us to protect the environment from polluting by waste papers and save resources. The papers are all made from trees and on the other side. The waste paper baler also help us on protecting forest resources on the earth.

The advantages of investing in a waste paper baler are:

Reduced labor costs - low labor input for mixed and office paper material disposal

Reduced disposal costs - removal of mixed and office paper from the waste stream

Revenue generation - recycled mixed and office paper sales

Improved workplace safety

Reduced fire hazards - less material buildup

Simplify mixed and office paper waste disposal

Recycled mixed and office waste paper is used to remanufacture new paper products, helping to save valuable time, energy and resources.

Q: Are paper balers suitable for all types of waste paper?

A: Paper balers are designed to handle various types of waste paper, making them suitable for most recycling needs.

Q: Can paper balers handle cardboard and packaging materials?

A: Yes, certain paper balers, such as cardboard crusher machines, are specifically designed to handle cardboard and packaging materials.

Q: Do paper balers require significant maintenance?

A: While regular maintenance is essential, Qunfeng paper balers are designed to be durable and require minimal upkeep.

Q: Are paper balers safe to use?

A: Yes, when operated correctly and with proper safety measures, paper balers are safe to use.

Q: Can paper balers be used in small businesses?

A: Yes, there are paper baler models suitable for small businesses with lower waste volumes.

Recycling waste paper process

Waste paper baler is a paper compactor machine which is used to compress and bale the waste paper like office waste paper, paper scraps, as well as old newspaper into a cube. Use the waste paper baler machine to make the waste paper which in loose condition to a tight bale. It is a very important step of the waste paper recycling. So Waste paper makes the recycling process more efficient.

Step 1: Collect the waste paper. Normally we can collect the waste paper materials from trash bins, offices, book stores, and schools etc. Then we can delivery them to professional recycling center.

Step 2: Sort and bale the waste paper. At this step, we also need the waste paper baler to help us finish the bale process. After the recycling facility accepts the waste paper from various sources, they will sort the paper based on the quality and material, structure and surface treatment. After sorting, we use the waste paper baler to bale the sorted paper, make it more convenient for storage and transportation. Then the recycling center will ship the paper bale to paper making factory.

Step 3: Wash the waste paper. After the sorted waste paper arrive paper making factory, we will wash it with soapy water to remove inks, plastic film, staples and glue. And then put them into a large holder where it is mixed with water to create paper slurry.

Step 4: Make new paper. After waste paper becoming paper slurry, we add different materials into the slurry to make it become new papers like office paper, newsprint, etc. When the new papers are dry, they are ready to go to the market for sale or use again.